AFH: solve Metal AM challenges for seamless integration and exploitation

Coordinated by Cetim, Additive Factory Hub (AFH) is a research platform that pools in one place the expertise and resources of different players (technical centers, research centers, academic and industrial partners). AFH benefits from the financial support of the Île-de-France region and is part of the Alliance Industrie du Futur national roadmap. Its objective is to develop the French industrial metal Additive Manufacturing (AM) activities. AFH thus works on innovation, development and integration of this technology. AFH defines a strategy and objectives with its members.

7 priority areas have been defined. The 10 members* of AFH finance, manage, carry out and benefit from the work achieved within the framework of this roadmap. R&D is driven by the needs of industrial innovation at the service of French competitiveness in the field.

In addition, AFH member companies** are integrated into the network and participate in the activities of the AFH community and certain collaborative projects. These are already mature projects in which at least one member company and 3 members take part.

AFH also offers its services to the entire ecosystem, through support and technological transfer services suited to their needs. Any business can become a member, partner or occasional user. It was founded so that businesses of all sizes can take ownership of Additive Manufacturing.

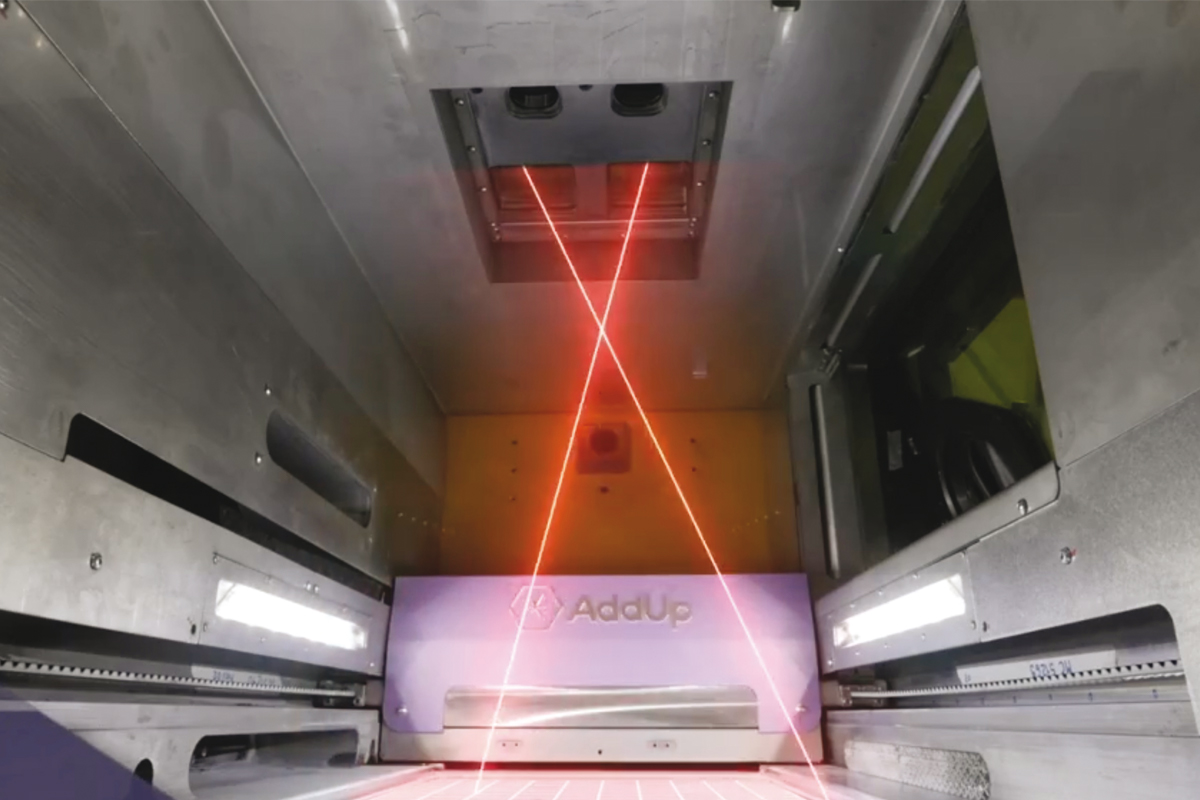

*ADDUP, AIR LIQUIDE, EDF, LNE, ONERA, SAFRAN, VALLOUREC, CETIM, CEA, ARTS & METIERS.

** MBDA, ARCELOR MITTAL.

AFH in numbers

AFH focuses on the mastery and control of the LPBF (Laser Powder Bed Fusion) and WAAM (Wire Arc Manufacturing) by addressing R&D work on:

→ Process instrumentation (monitoring of parameters influencing the final behavior of a part)

→ The development of the material-design-process trio to meet industrial specifications

→ The development of digital simulation and trajectory models for anticipating mechanical response of parts during their manufacture.

→ A database and associated statistical learning

Work on raw materials (powder) and Non-Destructive Control methods (X-ray tomography and ultrasound techniques) are also studied. Since 2021, AFH has been interested in the WLAM process (Wire Laser additive manufacturing) and from 2022, its roadmap will include the MBJ and DED-P (Powder Direct Energy Disposition).

AFH was founded on the principle of sharing and networking. Members have exchanged upstream with other actors to position themselves and work in complementary ways.

Members are, for example, in constant exchange with Technological Research Institutes (RTO) who work on AM so as not to duplicate existing or past research. Meetings with the Initiative 3D group of the Auvergne-Rhône-Alpes region and Addim Alliance in the New Aquitaine and Occitanie were organized to identify synergies and many collaborative projects are currently in progress between these entities.